The optical industry in 2025 is defined by a singular pursuit: precision at speed. For optical laboratories, high-volume clinics, and hospital ophthalmology departments, the Optical Lens Cutter Edger has transitioned from a backend utility to a frontline competitive advantage. As patient expectations for “same-day dispensing” become the norm rather than the exception, the ability to process high-quality eyewear in-house is reshaping the business models of vision care providers globally.

What Is a Lens Edger Machine?

The lens edger machine is a specialized piece of equipment used in optical laboratories and shops to precisely cut, shape, and finish the edges of eyeglass lenses so they fit perfectly into a chosen frame. This process, known as lens edging or finishing, is a critical final step in creating prescription eyewear. If you want to kown more visit our blog “What Is a Lens Edger Machine? Complete Guide for Beginners“

MARKET INSIGHTS

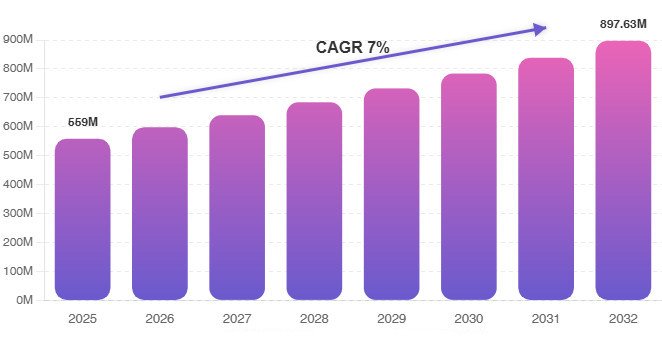

According to Intel Market Research, the global optical lens edger market was valued at USD 592 million in 2024 and is expected to grow from USD 633 million in 2025 to USD 942 million by 2032—reflecting a CAGR of 7.0%. This Optical Lens Edger Market Growth Analysis highlights the key dynamics, competitive landscape, and ongoing innovations shaping the industry’s outlook for 2025–2032. The message is clear: gaining control over the edging process is essential for improving profitability and delivering better patient satisfaction.

Modern lens cutter edgers now feature automatic pattern recognition, multi-material compatibility (including polycarbonate, Trivex, high-index, and glass), and integrated beveling for rimless frames. Dry and wet edging modes further ensure surface integrity across diverse prescriptions. These capabilities are no longer reserved for premium-tier equipment; mid-range models from certified manufacturers now offer comparable performance at accessible price points.

Anatomy of a Modern Patternless Edger

The terminology of the 2025 market is “Patternless” and “Intelligent.” The days of physical patterns and manual adjustments are largely behind us. Modern Ophthalmic Equipment integrates complex sub-systems into a unified workstation.

1. Digital Tracing and Blocking

The process begins with the “eye” of the system: the tracer. High-end units now employ 3D binocular tracing that maps the frame bezel’s curve (wrap), angle, and groove depth with micron-level accuracy. This data is fed to a smart blocker, which uses imaging systems to align the lens optical center automatically, compensating for parallax errors that often plague manual blocking.

2. Adaptive Edging Technology

The core of the machine—the edging chamber—has evolved to handle a vast array of materials.

- Smart Pressure Control: Advanced models, such as the LE-320P Auto Lens Edger, utilize “follow-up pressure” systems. These systems automatically adjust the clamping force based on the lens material (e.g., lower pressure for slippery AR-coated high-index lenses to prevent crazing, higher stability for CR-39).

- Multi-Wheel Configuration: A standard professional setup now includes specialized diamond wheels for different tasks: a coarse wheel for rapid material removal (glass vs. PC), a V-groove wheel for standard frames, and a polishing wheel for that “crystal clear” rimless finish.

- Automatic Emendation: This feature, found in leading instruments from manufacturers like Shanghai LINK, automatically recalibrates the machine upon startup to ensure that the left and right lenses are perfectly symmetrical, eliminating the “sizing drift” common in older equipment.

Choosing the Right Edger for Your Workflow

Selecting an optical lens cutter edger requires matching technology to operational scale:

- Small optical shops benefit from semi-automatic edgers with intuitive interfaces, low noise levels, and compact footprints.

- Mid-sized labs often opt for dual-mode (dry/wet) units with frame library integration and USB/Bluetooth connectivity.

- High-volume labs and hospital dispensaries require fully automatic, networked edgers capable of batch processing with minimal supervision.

Key performance indicators include cycle time (ideally under 90 seconds per lens), calibration stability across environmental variables, and ease of maintenance. LINK’s latest edger series, for example, reduces manual adjustments by up to 40% compared to legacy models, based on field data from partner labs in Germany, Mexico, and Southeast Asia.

Selecting a Manufacturer: The E-E-A-T Approach

In a market flooded with options, selecting a supplier requires due diligence based on Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

- Manufacturing Pedigree: A supplier’s reliability is often tied to their manufacturing roots. Shanghai LINK Instruments Co., Ltd., for instance, distinguishes itself by operating a complete manufacturing ecosystem in Shanghai. With over 15 years of experience and a facility that integrates R&D with production, they ensure that every Optometry Equipment unit, from slit lamps to edgers, undergoes rigorous quality control.

- Regulatory Compliance: Never compromise on safety standards. Ensure your equipment carries ISO 13485 certification for medical device quality management, as well as CE and FDA approvals. These are not just badges; they are verified indicators of safety and performance consistency.

- Global Support Network: An edger is a mechanical device that endures high stress. It will eventually need maintenance. Partnering with a company that offers a global service network and accessible technical support (via channels like WhatsApp or direct email) is crucial for minimizing downtime.

Future Trends: What Lies Ahead?

The trajectory of Optical Lab Machinery is pointing towards greater autonomy and integration.

- AI-Driven Diagnostics: Future edgers will likely incorporate AI to predict “slippage” risks by analyzing the lens coating and curvature before the cycle begins, adjusting parameters proactively.

- Dry Edging Technology: While wet edging remains the standard for the finest polish, “dry” edging (using milling bits) is gaining traction for its environmental benefits (water saving) and cleanliness, particularly in smaller retail settings.

- Integration with PMS: Seamless connectivity between the Practice Management System (PMS) and the lab equipment is becoming standard, allowing a prescription entered in the exam room to be queued on the edger instantly, reducing data entry errors.

“The modernization of the optical lab is not a luxury; it is a survival strategy. Data from 2024 suggests that independent practices with in-house finishing labs have a 20% higher patient retention rate compared to those who outsource exclusively.”

For professionals looking to upgrade their laboratory capabilities with robust, certified solutions, Shanghai LINK offers a range of high-performance instruments. Delivering precision-engineered edgers that meet the real-world demands of modern eye care.

Reference

¹ Optical Lens Edger Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2025-2032